CAD/CAM PROGRAMMING

2.5D CNC Machining

''Typical 3-axis machining tasks such as:

drilling, reaming or thread tapping ''

drilling, reaming or thread tapping ''

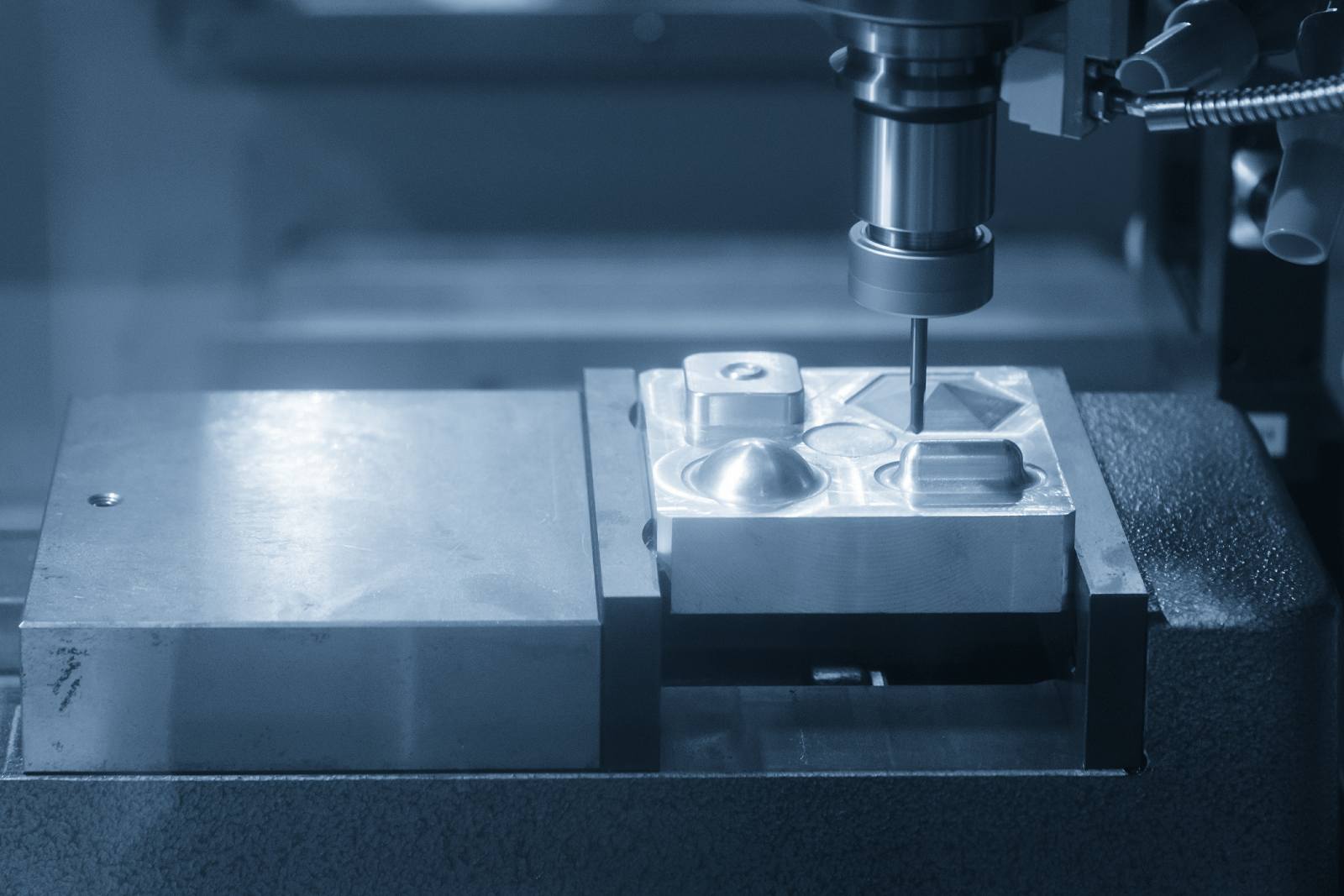

3D CNC Machining

''Simultaneous 3-axis machining tasks such as:

surface scanning, pencil strategy or thread milling''

surface scanning, pencil strategy or thread milling''

3+4th axis CNC Machining (Indexed)

It is a combination of 2.5D and 3D machining that allows you to optimize the number of operations of the component.

Interactive angle setting based on a 3D model reduces the possibility of error and makes the job easier and faster for the programmer.

Interactive angle setting based on a 3D model reduces the possibility of error and makes the job easier and faster for the programmer.

3+4th axis CNC Machining (simultaneous)

Simultaneous 4-axis machining use 3D machining tasks using an additional 4th axis moving simultaneously with other axes.

It allows for greater precision and accuracy of manufactured components..

It allows for greater precision and accuracy of manufactured components..

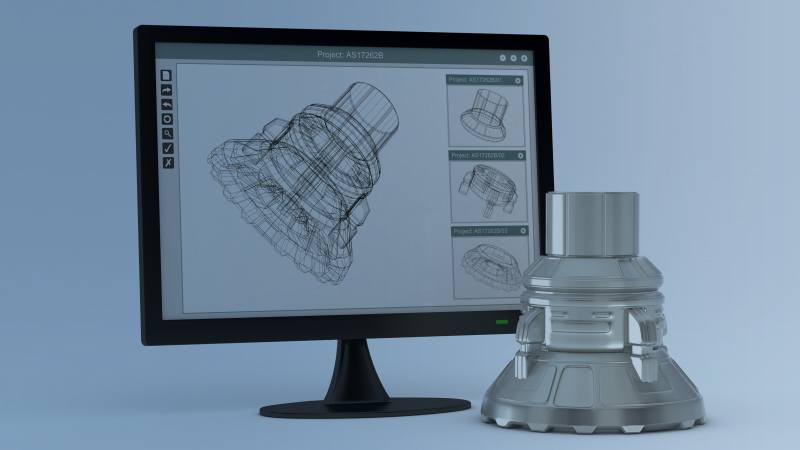

5 axis CNC Machining

Programming machining process in 5 axes provides unlimited possibilities to the size of the component and shapes.

In simplest terms, 5-axis machining involves moving a workpiece or cutting tool along five different axes simultaneously using a CNC machine.

Machining from one clamping set-up is faster.

Eliminates the time it takes to index. Prevents potential errors resulting from settings between individual angular positions. It is much more efficient than standard 3-axis machining.

In simplest terms, 5-axis machining involves moving a workpiece or cutting tool along five different axes simultaneously using a CNC machine.

Machining from one clamping set-up is faster.

Eliminates the time it takes to index. Prevents potential errors resulting from settings between individual angular positions. It is much more efficient than standard 3-axis machining.

We always choosing and using the latest strategies as often as possible, e.g.

Machining with a barrel cutters

Machining with a barrel cutters

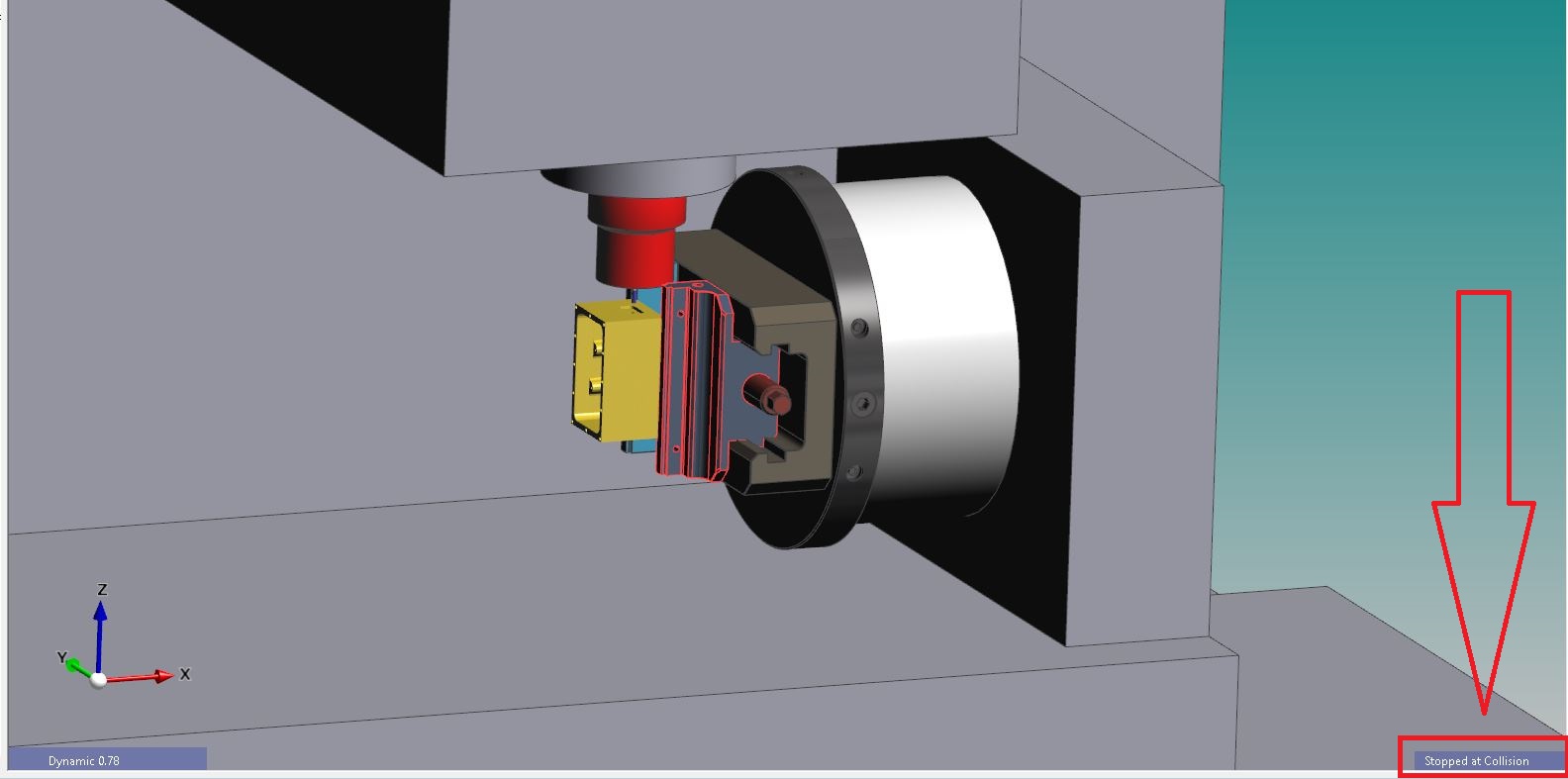

Better safe than sorry ! Automatic collision detection

Full machining simulation allows you to track the machine work progress and changes in the orientation of subsequent angular positions of all components.

This very important functionality ensures process safety for CNC machines.

Even small angular movements can generate large changes in the position of individual rotary axis elements and constitute a potential collision point.

Therefore, full visualization of machining is extremely important.Therefore, full visualization of machining is extremely important.jest niezwykle istotna.

This very important functionality ensures process safety for CNC machines.

Even small angular movements can generate large changes in the position of individual rotary axis elements and constitute a potential collision point.

Therefore, full visualization of machining is extremely important.Therefore, full visualization of machining is extremely important.jest niezwykle istotna.

An example of stopping the machining simulation during a collision between the tool holder and the vise. A too wide tool holder was used.